Weir公司Seaboard組合式鎖環(huán)(ULR)井口裝置:工程始于對話

真正的創(chuàng)新不是在真空室中完成的。Weir公司工程師的設(shè)計(jì)流程包含了與每個(gè)人(包括客戶,制造和供應(yīng)鏈專家)的協(xié)作對話溝通。這種方法使我們可以在實(shí)施之前在紙面上解決客戶痛點(diǎn)。在這個(gè)過程中,我們終設(shè)計(jì)出了客戶真正滿意的解決方案。

Seaboard™組合式鎖環(huán)(ULR)井口裝置是三部分網(wǎng)絡(luò)系列的主題。在傾聽客戶意見時(shí),我們了解到他們大的問題是安全性、時(shí)間和成本。因此我們從頭開始建立一個(gè)井口裝置,以直接解決這些問題。

在該井口裝置到達(dá)現(xiàn)場之前,Weir在制造方面的協(xié)作和精簡方法可以利用并行開發(fā)路徑來優(yōu)化效率。從設(shè)計(jì)到現(xiàn)場交貨的時(shí)間通常約為12周,比傳統(tǒng)井口裝置快6個(gè)月。

在安裝過程開始之前,我們團(tuán)隊(duì)仔細(xì)研究了傳統(tǒng)井口裝置的運(yùn)行程序。首先,安裝下一個(gè)之前需要拆卸防噴器(BOP),然后必須重新連接,且每個(gè)法蘭連接需要三到四個(gè)小時(shí)。另外,操作人員還必須等待水泥干涸,才能將BOP提升并移動(dòng)到下一個(gè)井口設(shè)備,手動(dòng)設(shè)置滑動(dòng)和修整外殼以匹配下一個(gè)閥芯。單這個(gè)過程可能就需要長達(dá)18個(gè)小時(shí)。

這個(gè)過程不僅耗時(shí),而且很危險(xiǎn),需要在一個(gè)不穩(wěn)定的環(huán)境里進(jìn)行火焰切割,焊接和研磨。時(shí)間越長,對人員和資產(chǎn)來說風(fēng)險(xiǎn)就越大。我們的目標(biāo)是簡化安裝,減少這些耗時(shí)的過程以及隨之而來的風(fēng)險(xiǎn)和成本,這是ULR能實(shí)現(xiàn)的操作性三重技術(shù)。

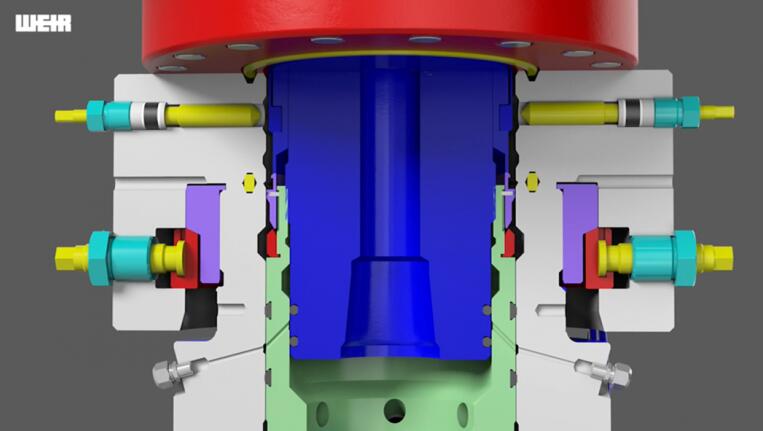

首先,ULR在單件式外殼內(nèi)采用了嵌套式系統(tǒng),縮短了整體堆疊高度,減輕了重量,使安裝更容易,安裝風(fēng)險(xiǎn)更小。技術(shù)人員可以使用心軸套管懸掛器,在不需要切割、焊接或研磨的情況下,通過旋轉(zhuǎn)工作臺(tái)和防噴器來運(yùn)行、著陸、循環(huán)和粘接套管。內(nèi)部鎖定密封組件消除了傳統(tǒng)井口設(shè)備上的多個(gè)泄漏路徑。

另一個(gè)提高安全性的策略是,Weir在尋找方法減少工作人員暴露在危險(xiǎn)環(huán)境中的時(shí)間。內(nèi)部鎖環(huán)組件和油管掛可為每套管柱節(jié)省6-8小時(shí)。通過快速連接的集線器,操作員可以比傳統(tǒng)的法蘭連接更快地將井口上的防噴器對準(zhǔn),著陸和固定,安裝時(shí)間從2小時(shí)減少到30分鐘以內(nèi)。另外,在恢復(fù)操作之前不再需要等待水泥干燥。

顯然,減少操作時(shí)間可以縮減相關(guān)的勞動(dòng)力成本。鉆井時(shí)間的一天可以為井口付出代價(jià),另外,通過降低風(fēng)險(xiǎn),還可以保護(hù)包括人員在內(nèi)的寶貴資產(chǎn),這是重中之重。

在ULR這個(gè)案例中,Weir充分聽取了客戶的意見,并提供了降低總體擁有成本的解決方案。接下來,我們將深入探討這個(gè)更安全、創(chuàng)新、節(jié)省時(shí)間的井口設(shè)備的特點(diǎn)。

關(guān)于鼎恒石油

四川鼎恒石油是Weir SPM的授權(quán)代理商,若需要購買SPM產(chǎn)品或需要了解產(chǎn)品詳細(xì)參數(shù)及相關(guān)疑問,可直接進(jìn)入鼎恒石油官網(wǎng)咨詢網(wǎng)站客服或者撥打銷售熱線18000522697。

四川鼎恒石油機(jī)械設(shè)備有限公司(http://www.zjncp.cn)是一家擁有進(jìn)出口經(jīng)營權(quán),長期從事國內(nèi)外石油天然氣設(shè)備和配件的專業(yè)銷售公司。鼎恒石油公司總部設(shè)在四川成都,在加拿大大不列顛哥倫比亞省成立了分公司。我公司與多家世界知名制造廠商建立了緊密的合作關(guān)系。

注:該文章由鼎恒石油編譯,轉(zhuǎn)發(fā)須注明出處。

附英文原文:

The Unitized Lock-Ring Wellhead: Engineering Begins with Conversation

True innovations don’t happen in a vacuum chamber. At Weir, our engineers make it part of the design process to collaborate with everyone—customers, manufacturing, and supply chain experts included. This approach allows us to address pain points on paper before they become reality. In the process, we engineer real-world solutions customers really appreciate.

Take the Seaboard™ Unitized Lock-Ring (ULR) wellhead, the subject of this three-part web series. In listening to customers, we learned their biggest issues are safety, time, and cost. So we built a wellhead from the ground up to directly address those issues.

Before the wellhead even arrives on site, Weir’s collaborative and streamlined approach to manufacturing leverages parallel development paths to optimize efficiency. Time from design to field delivery is typically about 12 weeks—six months faster than what’s required for a traditional wellhead.

And that’s before the installation process even begins. As a team, we took a hard look at running procedures on traditional wellheads. For the BOP, removal is required to install the next stage. Then it must be reconnected, with each flange connection taking three to four hours. Operators also have to wait for cement to dry before lifting the BOP up and off the next wellhead, manually setting slips and trimming casing to match the next spool. This procedure alone can take up to 18 hours.

Not only is the process time-consuming. It’s dangerous, requiring flame cutting, welding, and grinding in a volatile environment. The longer it takes, the greater the risk to personnel and assets. Our goal was to simplify the installation, eliminating these time-consuming procedures, along with the attendant risks and costs—an operational trifecta achieved with the ULR.

First off, the ULR features a nested system within a single-piece housing, resulting in an overall shorter stack-up height and reduced weight—making access easier and installation less risky. With mandrel casing hangers, technicians can run, land, circulate, and cement the casing through the rotary table and BOP with no cutting, welding or grinding required. An internal lock-down seal assembly eliminates the multiple leak paths found on traditional wellheads.

As another strategy for improving safety, Weir looked for ways to limit the amount of time workers are exposed in this dangerous environment. The internal lock ring assembly and mandrel hangers can save 6-8 hours per casing string. And with a quick-connect hub, an operator can align, land, and secure the BOP on the wellhead much faster than with a conventional flange connection, reducing rig-up time from two hours to less than 30 minutes. Plus, there’s no longer a need to wait for cement to dry before resuming operations.

Obviously, reducing the amount of time involved reduces the associated labor costs. A day of rig time could conceivably pay for the wellhead, plus, by reducing risk, you’re also protecting valuable assets, which include your people—that’s the underscore beneath every bottom line.

With the ULR, Weir has listened to customers and delivered a solution that lowers total cost of ownership. Next time, we’ll dive deeper into some of the features of this safer, innovative, time-saving wellhead.