Weir Oil & Gas公司推出簡化壓裂管匯系統(tǒng)

壓裂現(xiàn)場的管匯量更少

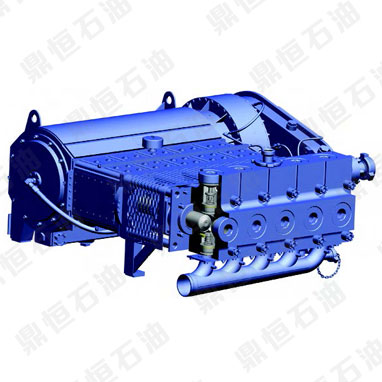

憑借新推出的簡化壓裂管匯系統(tǒng),Weir Oil & Gas公司大幅度減少了壓裂現(xiàn)場的管匯量,取代了傳統(tǒng)配置中的多根管線、無數(shù)回轉(zhuǎn)和連接,采用更安全,更直,更流線型的大孔設計。

非生產(chǎn)時間和成本減少

該系統(tǒng)可根據(jù)任何區(qū)域或環(huán)境進行自定義,旨在提高安全性和性能,大限度地降低壓降和侵蝕,從而延長設備使用壽命,并減少非生產(chǎn)時間,裝配時間以及材料和人工成本。

泄漏路徑更少,可靠性更高

在Weir Oil & Gas公司的簡化壓裂管匯系統(tǒng)中,我們使用更安全的API-6A法蘭連接取代了大量的錘擊由壬連接。這些標準化連接在現(xiàn)場很少需要緊固,且具有可靠的金屬密封墊圈,而且由于它們越來越少,大大減少了潛在的泄漏路徑數(shù)量。

裝配更快

該系統(tǒng)的壓力控制部件是線性和大口徑設計,其中有幾項已經(jīng)申請專利,極大地簡化和縮短了裝配過程。單入口和出口取代多個連接線。可調(diào)整的閥芯和旋轉(zhuǎn)法蘭允許在拉鏈歧管,壓裂樹和干線之間的快速對齊。

流體湍流更少

在要求苛刻的條件下產(chǎn)生加速磨損和壓降的定向流體變化也通過一條直線設計被小化,延長了產(chǎn)品的使用壽命。

經(jīng)過現(xiàn)場測試驗證

在近的一次現(xiàn)場測試中,Weir的簡化壓裂管匯系統(tǒng)的壓力控制部件比競爭對手之前的單線拉鎖接頭配置的持續(xù)時間多了三倍以上。

管道連接的數(shù)量從100個減少到12個,消除了88%的泄漏路徑(鉆臺現(xiàn)場設置將會改變總的減少量)。Weir配置的內(nèi)部CFD分析預測與相似設計相比,管道侵蝕減少了大約70%。

關(guān)于鼎恒石油

四川鼎恒石油是Weir SPM的授權(quán)代理商,若需要購買SPM產(chǎn)品或需要了解產(chǎn)品詳細參數(shù)及相關(guān)疑問,可直接進入鼎恒石油官網(wǎng)咨詢網(wǎng)站客服或者撥打銷售熱線18000522697。

四川鼎恒石油機械設備有限公司(http://www.zjncp.cn)是一家擁有進出口經(jīng)營權(quán),長期從事國內(nèi)外石油天然氣設備和配件的專業(yè)銷售公司。鼎恒石油公司總部設在四川成都,在加拿大大不列顛哥倫比亞省成立了分公司。我公司與多家世界知名制造廠商建立了緊密的合作關(guān)系。

注:該文章由鼎恒石油編譯,轉(zhuǎn)發(fā)須注明出處。

附英文原文:

Introducing the Simplified Frac Iron System

Less iron on the frac site.

With our new Simplified Frac Iron System, Weir Oil & Gas has dramatically reduced the amount of iron on the frac site, replacing multiple iron strings, numerous turns and connections found in traditional configurations with a safer, straighter, more streamlined large-bore design.

Reduced non-productive time and costs

Customized to any basin or condition, this system is designed to improve safety and performance, minimize pressure-drop and erosion—thus extending equipment life—and reduce non-productive time, rig-up time, and material and labor costs.

Fewer leak paths, greater reliability

Throughout Weir Oil & Gas’ Simplified Frac Iron System, we’ve replaced the numerous hammer-union connections with safer API-6A flange connections. These standardized connections, which rarely require tightening in the field, feature reliable metal-seal gaskets—and since there are fewer of them, we have dramatically reduced the number of potential leak paths.

Faster rig-up

The linear, large-bore design of the system’s pressure control components, several of which have patents pending, vastly simplifies and shortens the rig-up process. Single inlets and outlets replace multiple tie-in lines. Adjustable spools and rotating flanges allow for quick alignment between the zipper manifold, the frac tree, and the trunk line.

Less fluid turbulence

Directional fluid changes, which create accelerated wear and pressure drop in demanding conditions, are also minimized by the one-straight-line design, extending product life.

Field-tested, field-proven

In a recent field test, the pressure-control components of Weir’s Simplified Frac Iron System lasted more than three times longer than a competitor’s previous configuration, which also featured a single-line zipper tie-in.

The number of pipe connections was reduced from 100 to 12, eliminating the potential for leak paths by 88 percent (rig site set-up will vary total reduction). An internal CFD analysis of the Weir configuration predicted approximately 70 percent less pipe erosion compared to similar designs.